How to solve the problem-Precision on multihead weigher is not good

If you are running a business that relies on accurate weight measurements, then you know that a multihead weigher is an essential piece of equipment. However, if your current machine is not giving you the level of precision that you need, don’t worry – there are ways to improve it! In this blog post, we will discuss 12 methods that can help you get the most precise readings from your multihead weigher.

1. Understand the factors that affect precision

The first steps to take if you want to improve the precision of your multihead weigher is to understand the factors that can affect its accuracy. These include everything from the type of product being weighed to the environmental conditions in the room where the machine is located. By understanding these factors, you can make changes that will help improve the precision of your machine.

2. Use the correct settings for your product and material

Make sure that you are using the correct settings for your product and material. Every multihead weigher is different, so it’s important to consult your owner’s manual or the manufacturer to find out what the best settings are for your machine. Once you have these settings, be sure to use them every time you weigh something.

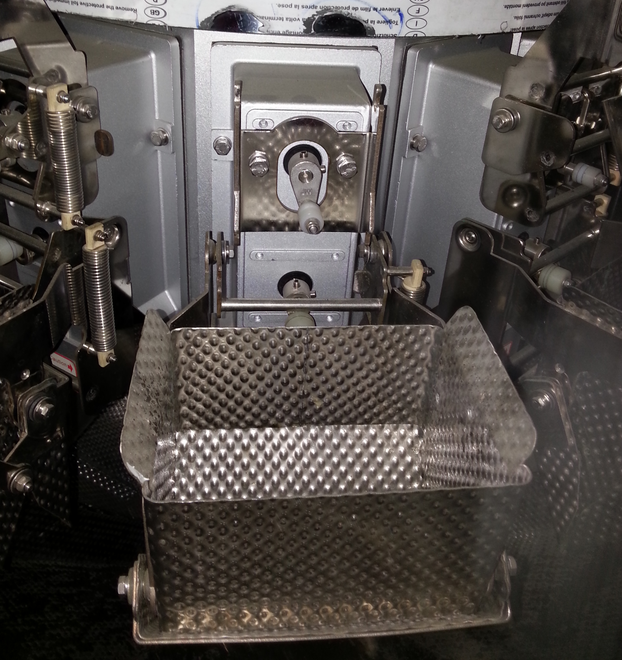

3. Check if all hoppers work normal

⑴Mechanical failure

⑵Touch screen’s parameter adjustment or the failure of the circuit

The first step is to enter the manual test page of multihead weigher, and test the weigh hopper one by one to check whether the weigh hopper can open and close the door normally, and notice the sound of opening and closing door is normal or not.Set Zero on the main page, and choose all hoppers, let the weigh hopper run three times continually, then come to the Read load Cell Page, observe which hopper can’t return to zero.

If some hopper can’t return to zero, which means this hopper’s installation is abnormal, or the load cell is broken, or the modular is broken.

And observe whether there is a large number of communication errors in the module of the monitoring page.

If some hopper’s door opening/closing is abnormal, it need to check whether the weigh hopper’s installation is not correct. If yes,install it again.

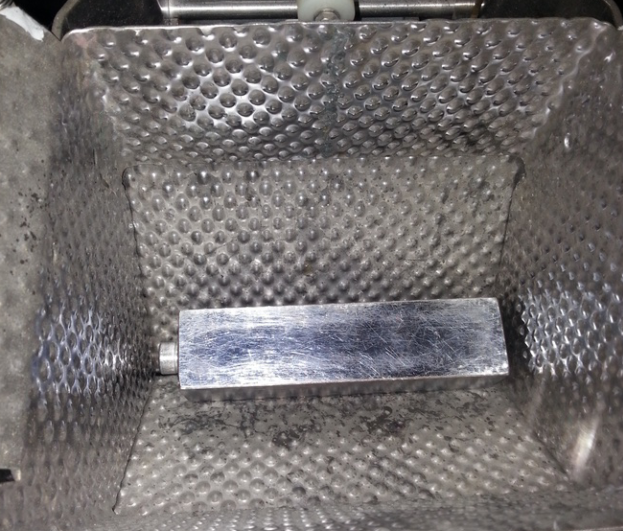

If all hopper can open/close the door correctly, the next step is to take down all the weigh hopper to see whether there are material on the weigh hopper’s hanging spare parts.

Last to ensure no material clutter on each weigh hopper’s spare parts, then make the calibration of all weigh hopper.

4. Check the calibration of your machine regularly

It is important to make sure that your multihead weigher is properly calibrated on a regular basis. If it is not, then its readings from load cell will not be accurate. Fortunately, checking the calibration is relatively easy to do – most manufacturers will provide instructions on how to do this.

5. Keep your weigher clean and free of debris

A dirty multihead weigher can also affect its precision. Any build-up of dust or debris on the sensors can interfere with the readings, so it’s important to keep your machine clean. The best way to do this is to follow the cleaning instructions that came with your machine.

6. Use proper weighing techniques

There are certain techniques that you can use when weighing products that will help improve the precision of your readings. For example, make sure that you place the product in the center of the tray and do not overload it. Additionally, if you are weighing multiple items, be sure to weigh them one at a time.

7. Make sure the product is stable on the scale

If the product is not stable on the scale, then the readings from load cell will not be accurate. To help ensure stability, use a flat tray or surface when weighing your product. Additionally, make sure that there are no vibrations in the area where the scale is located.

8. Allow the weigher to stabilize before taking a reading

When you turn on your multihead weigher, it will take a few moments for it to stabilize. During this time, the readings may not be accurate. Therefore, it’s important to wait a few moments after turning on the machine before taking a reading.

9. Store products in a consistent manner

One way to help improve the precision of your multihead weigher is to store products in a consistent manner. This means that you should always weigh the same type of product in the same position on the scale. Additionally, try to keep the products as close to the center of the tray as possible.

10. Weigh similar products together

If you are weighing a variety of different products, it can be helpful to weigh similar products together. This will help to even out any inconsistencies in the weight of the individual items.

11. Use the tare function

Most multihead weighers have a tare function that allows you to reset the scale to zero before

12. Regularly test products to ensure accuracy

One way to tell if your weigher is giving accurate readings is to test it regularly with known weights. This can be done by weighing a standard weight on the scale and then comparing the reading to the actual weight. If the two values are not close, then there may be an issue with the weigher that needs to be addressed.

If your multihead weigher was bought from Smartweighpack, please contact with us, we will help you solove the problem of weighers. Contact us for more maintainence tips for multihead weigher! export@smartweighpack.com.