Packaging Machine Manufacturers – Smart Weigh

Today, packaging is considered to be one of the most important factors of product marketing and branding. A well-designed and well-manufactured package is one of the primary reasons why a consumer buys your product.

Therefore, packing of products is becoming a very critical task, as a food retails manufacture or contract companies, how to choose the right packing machine to stand for their package becoming important.

As a leading turn key packaging machine manufacturer, Smartweigh could provide a full rang of of weighing and packing machine to meet customer’s different kinds of package requirement.

Smart Weigh customized all kinds of weighing and packing machines for food and non food to suit your specific applications and packing environment, as well as your regulatory and industry requirements. We smartweighpack company is the world packing machine market leader for VFFS (forming, filling and sealing) and weighing (filling and counting), horizontal packaging machines and capping machine. Pharmaceuticals, fresh food, frozen food, seafood, pet food, cosmetics, powdering product, beverages and household products – we have machines for packing or capping all types of products, including seeds and dairy leisure products.

Packaging Machines manufactured by Smart Weigh

Smart Weigh offers a wide range of European quality packaging equipment. For the packaging of industrial products in the catalog of our website, you can find:

Vertical form fill sealing Packing machine

This kind of packing machine, known as a vertical form-fill-sealing (VFFS) machine, is used for packaging different products such as juice, vegetables, snacks, etc. The VFFS machine is equipped with multihead weigher, linear weigher, or cup filler, or auger filler to fill the granule or powdery product. A vertical sealer is attached to the hopper and it creates a single package from the contents inside. You can make the pillow bag, pillow gusset bag, 4 side seal, quad bag or even standing up zipper bag with vertical form fill sealing machine by roll film, it is much comfortable cost and space saved compare with rotary packing machine, thus, if you are start up business maker, this machine can be the first choice to entry this market.

This equipment is used for packing the product into premade pouches, they can be doy pouch with zipper, flat bag, bottom gusset, or quad bag zipper of all types.

Compare with vertical form fill sealing machine, this packing machines are more welcome on the market if you want to specific and advertising your brand and your package, your bags will looks nicer and more attractive compare with pillow bag, besides, premade bag can be re-open and re-cycled used if product is food not finished yet, it can protect food from damaged or ruin by dusty. You could properly expect a lots of coffee maker, dried fruit manufacture would more likely choose rotary packing machine other than pillow bag, as it can more easily to enter the market and and get better price with such nicer package.

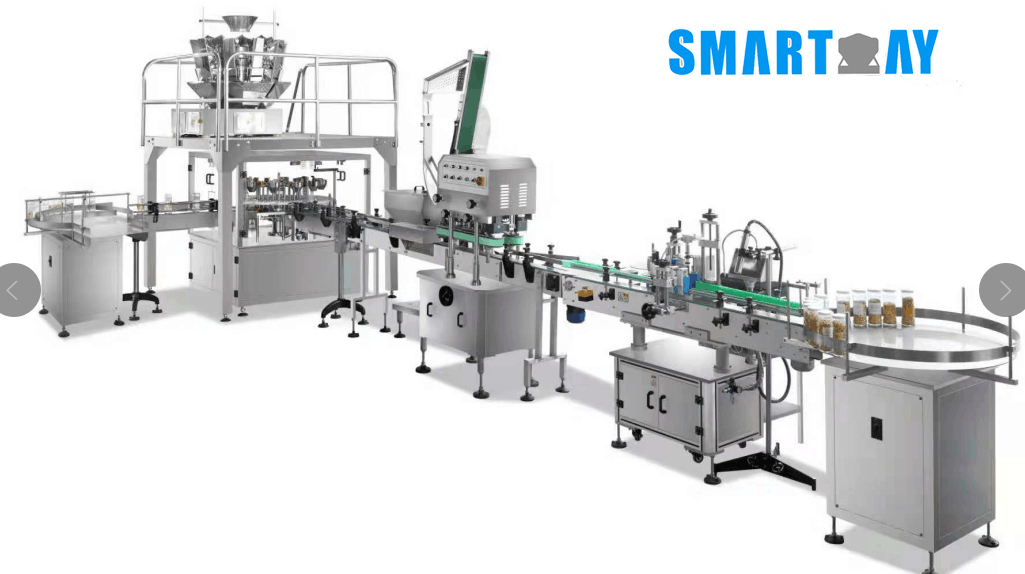

Bottle Filling, Capping and Sealing Machines

With the trend of environment protection, glass filing and capping is becoming more and more popular, especially for pharmaceuticals, powdery, dried fruit or cannabis processing and capping. These machines are used for filling and capping, and sealing of the glass bottles, plastic bottles, cans, aluminum cans and other metallic containers.

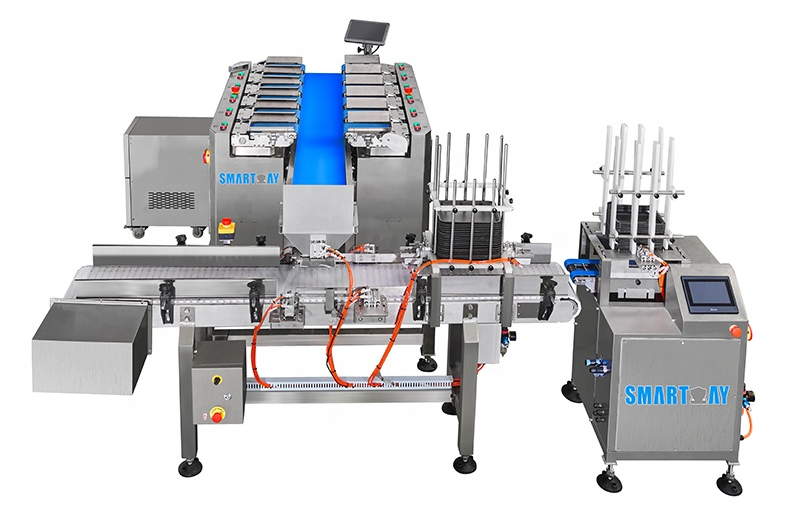

Tray Filling and Sealing Packing Line

This kinds of packing concept are mostly applied in ready meals, express food, fast food, or fresh meat market. It can equipped with smartweighpack meat weigher( Srew weigher), linear combination (SW-LC12) weigher, vegetable weigher(SW-ML14), noodle weigher to pack all fresh/ frozen food into vacuum or non vacuum.

Advantages of Smart Weigh Packaging Machine

There are many benefits from this type of machine, which include:

- Maximum Accuracy

- Consistent package quality

- Very high production speed

- Long service life

- Ease of handling, with friendly program page with explanation for all basic parameter, DIY program page for any future requirement

- Quick format change-no tools needed to disassemble or install the machine

- High profitability

- Low energy and maintenance costs, machine electrical part are friendly used for all kinds of smartweigh weigher, from 10 head to 24 head, spare part are flexible to exchange.

- Spare part update, no shortage of spare part for old version of machine, we will design our machine with part can be flexible exchanged between old and new version, and before we upgrade our machine, we would stock a batch of spare part for any future maintenance for old version, thus customer no worry about the shortage of old part.

- Fast delivery of spare parts, within 4-5 days by DHL OR Fedex

- Less human error, high quality products, and reduced costs.

- 24 hours on line support and well trained servicemen for all kind of weighing and packing systems like vffs , rotary packing, bottle fill capping or tray filling and capping with English speaking

Let’s Sum Up

A good marketing mix can be summed up in three words: “Packaging, packaging, and more packaging.” Your product may be excellent, but if people don’t know about it, then it won’t sell. So, buy a packaging machine from Smart Weigh to get your best package.

- We are a manufacturer, not an importer of packaging equipment. We are experts in our field. Our equipment is designed for the market and is made to perform, every packing system would be evaluated and testing with same or similar product before delivery to customer, it can enhance the machine capability and eliminated any unexpected trouble after connection.