Ready Meals Packaging Machine Solutions: Compare Prices and Features

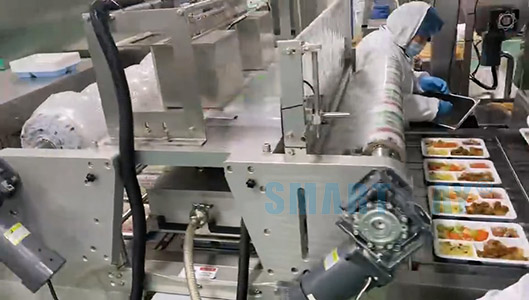

Ready meal packaging machines are essential for food businesses aiming to enhance operational efficiency, product consistency, and customer satisfaction. These machines automate the packaging process, ensuring that meals are sealed properly, weighed accurately, and presented appealingly.

Types of Ready Meal Packaging Machines

Weighing Machines

Multihead Weighers: These machines are designed to weigh various ready to eat food and cook meals precisely, ensuring portion control and minimizing waste.

Packing Machines

Tray Sealing Machines: They provide airtight seals for trays, which help in extending the shelf life of the ready meals.

Thermoforming Machines: These machines create custom trays from plastic films, allowing for flexibility in packaging different meal types.

Key Features to Consider

Automation Level: Higher automation levels can significantly reduce labor costs and increase production efficiency.

Capacity: Depending on the model, capacities can range from 1500 to 2000 trays per hour, making them suitable for different scales of operation.

Accuracy: Precision in weighing can reduce food waste by up to 10%, which is crucial for maintaining profitability and consistency.

Comparing Prices

Entry-Level Machines: These are more affordable and suitable for small businesses or startups with lower production volumes.

Mid-Range Models: These machines offer a balance between cost and features, making them ideal for medium-sized businesses.

High-End Systems: These are equipped with advanced features and higher capacities, making them suitable for large-scale operations.

Brand Comparisons

Known for its reliable and customized packaging solutions. Their machines are designed to meet diverse needs, ensuring durability and excellent performance. As a ready meals packaging machine leading manufacturer, the boss of Smart Weigh was invited to share in ready to eat food and central kitchen exchange conference.

Maintenance and Operating Costs

Routine Maintenance: Regular maintenance is essential to keep the machines running efficiently. This includes cleaning, parts replacement, and periodic inspections.

Operating Costs: Consider energy consumption and labor costs associated with operating these machines. Opting for energy-efficient models can lead to significant savings.

Customization and Scalability

Custom Solutions: Many manufacturers offer customized solutions to meet specific packaging needs. This can include modifications to handle different meal types or packaging materials.

Scalability: Choose machines that can be easily upgraded or scaled up as your business grows. This ensures long-term usability and cost-effectiveness.

Technological Advancements

Real-Time Monitoring: Advanced packaging machines come with central control systems that allow for real-time monitoring and adjustments, improving efficiency.

Washdown Design: Machines with washdown designs are easier to clean, ensuring hygiene and reducing downtime.

Case Studies and Success Stories

Efficiency Gains: Many businesses have reported significant efficiency gains by adopting ready meal packaging solutions. These machines have helped reduce labor costs, minimize waste, and improve product quality.

Diverse Applications: Ready meal packaging machines are versatile and can handle various types of meals, from salads and pastas to more complex dishes, ensuring flexibility in production.

Conclusion

Choosing the right ready meal packaging solution involves careful consideration of cost, features, and scalability. By investing in the appropriate equipment, businesses can enhance their operational efficiency, reduce waste, and improve product quality, ultimately leading to increased profitability.